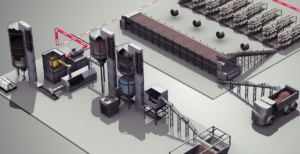

Learn all about good practices in Kilbra equipment, its benefits and examples.

the exercise ofgood practices within aviaries it is very important for the good functioning, safety and greater durability of the equipment. This is because she will ensure that all equipment is suitable for carrying out the work.

It is worth remembering that the best performance of the equipment directly reflects on the well-being of the birds, thus increasing the productivity and quality of the eggs.

If you want to learn a little more about good practices in Kilbra equipment, stay with us.

What does good practice mean?

Good practices within aviaries are a set of operational, technical and administrative actions. Working together, they aim to provide the equipment with the correct functioning of all parts of the system, such as: Egg and manure collection mats, water and feed supply, and the air conditioning system.

In addition, it directly interferes with the working conditions of the aviary. This is because good practices also influence employee productivity and safety.

How about we better understand the impactnegative of not executing good practices?

What is the negative impact?

When we talk about automated equipment, we soon think of optimizing production processes, reducing humanized labor, safety and quality of life for birds, among other reasons. This means that to make equipment automatic, we use electrical, electronic and mainly mechanical resources that generate power to the systems.

In this way, all electrical, electronic and mechanical resources require periodic maintenance, such as lubrication, cleaning, alignment, among others that we will talk about in detail later on. So, once good maintenance practices are left aside, the systems are harmed and in the medium term the main objective, which is the automation of processes, is jeopardized by the malfunction of chains, bearings or damaged electrical parts. It can generate productivity and even financial losses to the administrative sector.

What are the objectives of good practices?

The objectives of good practices must be clear to all employees. Thus, together, the entire team can contribute to the proper functioning of the equipment.

Check out the main best practices

General instructions:

- Check all equipment to ensure employee and bird safety.

- Check the alignment of the batteries, if it is not completely aligned, correct it.

- All damaged parts must be replaced immediately.

- When carrying out any maintenance, whether electrical or mechanical, turn off the general power supply to the equipment.

cleaning instructions

- Clean equipment daily.

- Remove moisture from equipment.

- Protect electrical appliances to avoid contact with water.

- Cleaning products can accelerate corrosion, so carefully select the least corrosive products.

Conveyor conveyor care

- Check tension, fit and alignment.

- In the case of tarpaulin, check that there are no damages and breaks.

- Check the welds of the mats daily.

- Carry out the collection of manure at most every 2 days to avoid overweight.

Pick-up and traction systems

- Check chain and pulley adjustments.

- Lubricate chains and bearings according to manufacturer’s instructions.

- Check chain tension, if necessary retighten.

- Monitor the state of conservation of nylon wheels or guides, if necessary, change them.

Battery care

- Entry of birds into the battery must occur from the bottom floors upwards.

- Removal of birds in the battery must occur from the floors from top to bottom.

- Check that there are no parts inside the feeders.

- Remove all obstructions from feeders and cages.

Team suggestion

A specialized technician from theWorkplace safety to monitor and deal with more technical and specific conditions for each situation. But by following the good practice suggestions above, safety, bird welfare and equipment durability will be improved.